New Direction in Photocuring Technology: In-depth Analysis of Polymeric Photoinitiators

Abstract:

With the improvement of environmental protection and performance requirements, polymeric photoinitiators have become a research hotspot. This article compares traditional small-molecule initiators, analyzes the unique advantages of macromolecular structures (such as low toxicity and efficient curing), and looks ahead to their development prospects in high-end photocurable materials.

Photoinitiator (PI) is one of the main factors that determine the curing rate and degree of UV systems.

Traditional PI is a small molecule containing photoactive groups and has poor compatibility with polymers. The PI and photolysis fragments remaining in the product are likely to migrate and volatilize, causing the product to age and turn yellow, and giving off odors and showing toxicity, which restricts the application of photocuring systems in food and medicine packaging and other aspects.

Polymeric photoinitiator (PPI) is an effective way to solve the above problems and has become an important topic in the research field of photoinitiators. This type of initiator is a polymer with multiple photoactive groups in the main chain or side chain, and they has no volatility or migration properties, which helps to improve the weather resistance, gloss and other properties of the product. PPI can also be used to prepare block and graft copolymers.

Compared with small-molecule PI, PPI has a series of advantages:

① Since the PPI molecular chain contains multiple photoactive groups, these groups can interact with each other, improving the absorption of light energy and increasing its initiation activity.

② The macromolecular chain segments of PPI can react with photoactive groups to generate more primary free radicals.

③ The macromolecular chain segments of PPI hinder the coupling termination between free radicals, which is equivalent to extending the lifespan of primary free radicals and promoting the occurrence of the initiation reaction.

④ By copolymerizing different monomers, PPI containing a variety of photoactive groups can be synthesized, and the synergistic effect between the groups endows PPI with higher initiation performance.

However, PPI also has the following disadvantages:

① The macromolecular chain segments of PPI will embed the initiation groups, hindering their approach to monomers and reducing the initiation efficiency.

② The mobility of PPI is low, and its diffusion rate in the system is slower than that of small-molecule PI. Therefore, a relatively large amount of PPI is required.

Sometimes PPI will cause the gel point of the system to be reached prematurely, resulting in the gelation of the system or the formation of products with a relatively low molecular weight.

Today, we recommend three high-performance polymeric α-hydroxyketone photoinitiators, which have unique advantages in the field of UV curing:

1.★ Photoinitiator 150:

This orange-yellow viscous substance has a molecular weight of about 2000, and its structure can be regarded as an oligomer formed by connecting photoinitiator 1173 to methyl vinyl. Although the photoinitiation efficiency is about 25% of that of photoinitiator 1173, its special structure can generate multiple free radicals after illumination, creating a local high-concentration free radical environment, significantly improving the anti-oxygen inhibition ability, and effectively accelerating the photopolymerization rate.

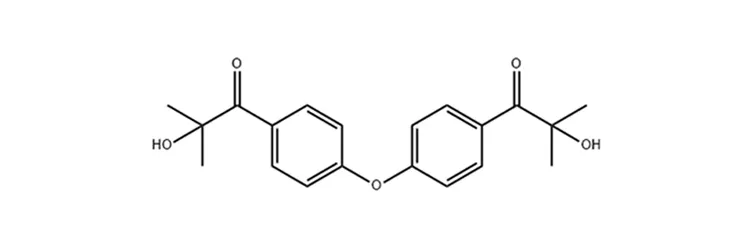

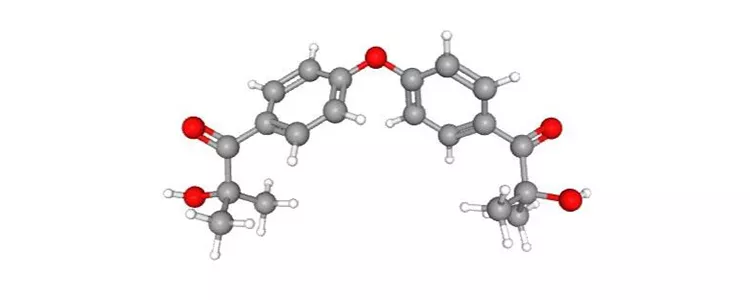

2. ★ Photoinitiator ONE:

As a representative of α-hydroxyketone oligomers, its photoactivity is comparable to that of photoinitiator 184 and 1173, and it also has excellent anti-oxygen sensitivity. It is especially suitable for low-viscosity thin coating UV coatings and can achieve excellent surface curing effects. In addition, its low volatility characteristics keep the odor of the bulk and photolysis products at a low level.

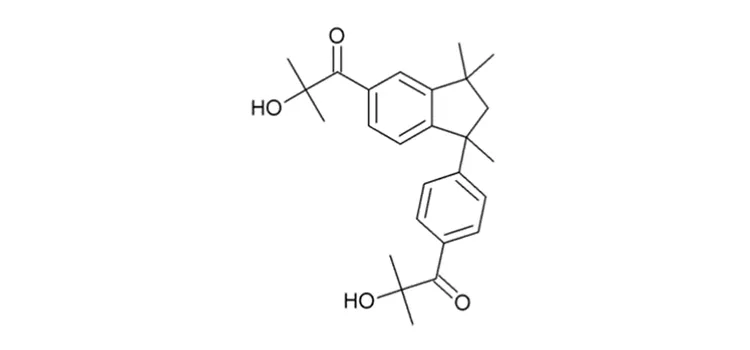

3. ★ Photoinitiator 160:

This innovative product performs outstandingly in terms of reactivity, which is significantly improved compared with traditional α-hydroxyketones. Its molecular structure has been specially designed, and the absorption spectrum is red-shifted, which perfectly matches the coloring system of conventional UV equipment. It also performs excellently in transparent coatings and is the first choice for systems requiring low VOC, low migration and low extraction values.

These three products have their own characteristics and can meet the diverse needs of photoinitiators in different application scenarios. If you have any product requirements or technical consultations, please feel free to contact us. We will provide you with detailed product technical information and sample support.

Our professional team will recommend the most suitable photoinitiator solutions according to your specific application requirements, helping to improve the performance of your products.

Look forward to cooperating with you!

Previous: Guide to Recommended Photoinitiator Models in the Common UV Curing Industry

Next: No More