The 'Black Technology' Coating Curing Magic : Instant Curing is No Longer a Dream —— Cationic photoinitiator PAG-201

Have you ever thought that coating curing could be as fast as 'performing magic'?

Today, we are going to uncover a 'black technology' in the photocuring coating industry —— the mixed type triphenyl sulfonium hexafluoroantimonate salt propylene carbonate solution.

It can not only achieve instant curing of coatings but also perform excellently on complex shapes and thick coatings! How exactly does it do this? Let's take a look!

1. What is the mixed type triphenyl sulfonium hexafluoroantimonate salt propylene carbonate solution?

This is a highly efficient photoinitiator solution, composed of a mixture of triphenylsulfonium hexafluoroantimonate and carbonate acrylate. Under ultraviolet light irradiation. It can rapidly initiate the polymerization reaction in the coating, achieving rapid curing.

2. What is its curing principle?

(1) The role of photoinitiator

Triphenylsulfonium hexafluoroantimonate, as a photoinitiator, generates cationic active species (such as protic acids or Lewis acids) after absorbing light of a specific wavelength.These active species initiate the cationic polymerization of carbonate acrylate monomers or prepolymers, forming a cross - linked structure and enabling the rapid curing of the coating.

(2) Cationic polymerization

The cationic polymerization reaction has the characteristics of living polymerization. Even if the light irradiation stops, the reaction can still continue, making it suitable for the curing of thick coatings or shaded areas.

3. Which light sources is it suitable for?

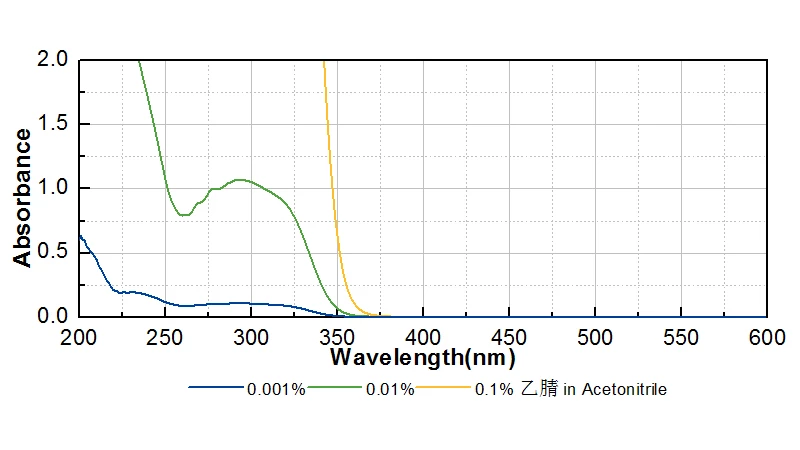

This solution is highly sensitive to ultraviolet light (UV), especially in the wavelength range of 250 - 350 nm, where it works best. Some formulations can even work under visible light at 400 - 450 nm, but the efficiency is relatively low.

4. What are its advantages?

(1) Instant curing:

Under ultraviolet light irradiation, the coating can be completely cured within seconds to minutes, greatly improving production efficiency.

(2) Deep - layer curing:

It is suitable for the curing of thick coatings or complex shapes, solving the problem that traditional coatings are difficult to cure uniformly.

(3) High stability:

The system is stable when not irradiated, which is convenient for storage and use.

5. In which fields is it used?

(1) Electronics industry

Photoresist: As a photosensitizer for photoresist, it is used in the photolithography process in semiconductor manufacturing.

Electronic packaging materials: It is used for packaging materials to improve their heat resistance and mechanical properties.

(2) Chemical industry

Catalyst: As a catalyst for organic synthesis reactions, it improves the reaction efficiency.

Polymer material modification: It is used to improve the properties of polymer materials, such as heat resistance and mechanical strength.

(3) Coating industry

Photocuring coatings: As a photosensitizer for photocuring coatings, it is used in coatings and inks that require rapid curing.

(4) Pharmaceutical industry

Medicine synthesis: It participates in the medicine synthesis process as an intermediate or catalyst.

The mixed type triphenyl sulfonium hexafluoroantimonate salt propylene carbonate solution, with its high - efficiency photo - initiating performance and rapid curing ability, is becoming a'star product' in the photocuring coating industry. Whether in industrial production or daily applications, it can make coating curing faster and more efficient!

If you are interested in this ‘black technology’, please contact us to obtain detailed product data.