Analysis of UV Offset Printing Ink Technology: From Formulation Design to Water-Ink Balance Optimization

Abstract:

Offset printing, as the most widely used lithographic printing technology in the printing field, its core lies in the precise control of the principle that oil and water repel each other. This paper systematically introduces the characteristics and key preparation points of UV offset printing inks, including key technical requirements such as high viscosity, anti-emulsification, and rapid curing, and provides reference formulations for four-color inks.

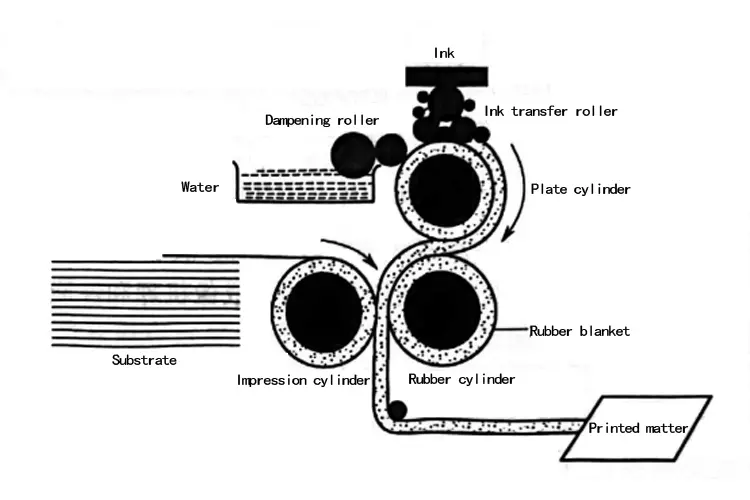

Offset printing, also known as lithographic printing, is the most widely used printing method in the printing field. The image-text areas and non-image-text areas of an offset printing plate are basically on the same plane, with only a slight difference in height. It uses the principle that oil and water repel each other for printing: the image-text areas are hydrophobic (ink-loving), and the non-image-text areas are hydrophilic (ink-repelling). During printing, the non-image-text areas are first wetted with fountain solution, while the image-text areas repel the fountain solution; then the ink is transferred by ink rollers, with the image-text areas accepting the ink and the non-image-text areas repelling it; the ink on the image-text areas is then transferred to the rubber cylinder and subsequently to the substrate, making it an indirect printing process.

The offset printing process is shown in the figure.

I. Characteristics of offset printing inks

✿ 1. The ink layer is very thin, generally around 2 microns in thickness for a single color.

✿ 2. Since ink rollers and dampening rollers alternately contact the printing plate, high requirements are placed on the printing adaptability of the ink, while preventing emulsification of the ink.

✿ 3. Offset printing has a high speed, generally ranging from 100 to 400 meters per minute.

✿ 4. Offset printing inks have high viscosity, high pigment concentration, and strong tinting strength.

✿ 5. The ink is transferred to the substrate by elastic rubber rollers, so the printing pressure is relatively small and uniform, with high overprinting accuracy, good image-text reproducibility, clear dots, and rich layers.

II. Preparation of UV Offset Printing Inks

✿ 1. Based on the characteristics of offset printing inks, the ink must have good water resistance and avoid emulsification during printing.

✿ 2. Due to the high printing speed, the photocuring speed of the ink must be considered, and oligomers and reactive diluents with high functionality should be selected.

✿ 3. Given the high pigment concentration, oligomers with good wettability to pigments need to be used.

✿ 4. Photoinitiators

❖ Photoinitiators are usually used in combination of ITX and 907:

❖ For magenta and yellow inks, photoinitiator 651 can be added;

❖ For black inks, photoinitiator 369 is the main component, combined with photoinitiator DETX or photoinitiator ITX;

❖ For white inks, photoinitiator TPO and photoinitiator 819 are the main components, combined with photoinitiator 184 or MBF.

❖ The dosage of photoinitiators is usually more than 6%. Sometimes, a small amount of tertiary amine can be added to improve the photocuring rate.

❖ For inks used in food and pharmaceutical packaging printing, macromolecular photoinitiators can be selected, such as our products photoinitiator 150, 160, 127, and ONE.

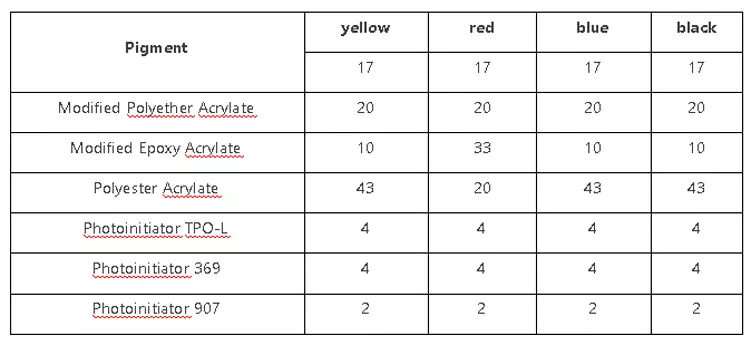

✿ Reference Formulation for Ordinary UV Offset Printing Ink

III. Difficulties in UV Offset Printing Inks

At the beginning of the article, it was mentioned that offset printing inks rely on the principle of oil-water repellency for printing. In actual printing processes, UV offset printing inks have a narrow tolerance for the amount of fountain solution, making the water-ink balance difficult to control. Acrylate oligomers and reactive diluents usually contain high-polarity groups such as hydroxyl, amino, and carboxyl groups, which have strong affinity for fountain solution. Polyester acrylates have relatively good water resistance, but their hardness, abrasion resistance, and solvent resistance are relatively poor. A new oligomer, diallyl phthalate (DAP), launched by our company, can well solve this oil-water balance problem.

Its specific characteristics are as follows:

✿ 1. Excellent Anti-Emulsification Property

It possesses unique oil-water balance performance, which not only prevents the non-image-text areas from being contaminated by ink but also ensures sufficient ink transfer in the image-text areas.

✿ 2. Excellent Heat Resistance

After curing, the DAP prepolymer forms a highly cross-linked thermosetting resin, which can withstand high temperatures during the offset printing process (such as drying heat or frictional heat during high-speed printing) and avoid ink softening or sticking.

✿ 3. High Gloss and Leveling Property

The cured DAP resin has a smooth surface, which can endow the ink with a high-gloss effect. Meanwhile, it improves leveling property and reduces defects like orange peel or pinholes on the surface of printed matter.

✿ 4. Chemical Stability and Solvent Resistance

It has strong resistance to oils, acids, alkalis, and common post-printing solvents (such as ethanol and esters), making it suitable for printed matter that requires subsequent processing (e.g., lamination, varnishing).

✿ 5. Low Shrinkage and Strong Adhesion

It has a low volume shrinkage rate during curing, which reduces stress on substrates (such as paper and plastic films). Meanwhile, it has good compatibility with pigments and fillers, and exhibits strong adhesion.

✿ 6. Electrical Insulation (Special Applications)

In special offset printing inks for electronic circuit printing and other scenarios, the insulating property of DAP can meet the requirements of short-circuit prevention or high-frequency signal transmission.

Ⅳ. Application of DAP

Oligomer Diallyl Phthalate (DAP)

In addition to high-end packaging inks (such as food and pharmaceutical packaging, which require heat resistance and migration resistance), DAP prepolymers can also be applied in metal decorative printing (such as cans and labels, which require high-temperature sterilization resistance), electronic printing inks (such as PCB solder masks), etc.

If you have any product requirements or technical inquiries, please feel free to contact us at any time. We look forward to cooperating with you!